All mines recognise the need for a reliable, robust, and low maintenance communication system to enhance safety and production. The Becker Varis VHF leaky feeder system (smartcom®) is world-renowned for its reliability, robust performance, and maintainability.

Becker Varis recognises that one size doesn’t fit all and that customers needs vary with the size of their mines and budgets.

Leveraging off the successful and original smartcom® RNG-AMP we now offer an option for all mines to access the world’s premium VHF Leaky Feeder system that also provides an upgrade path should you wish to enhance the system at a later stage.

30MHZ BANDWIDTH

The industry-leading 30MHz bandwidth allows multiple voice and data channels that operate simultaneously with super-low intermodulation noise levels.

RF GAIN

The industry’s highest RF Gain pilotless (in manual mode) amplifier with automatic and manual gain modes allows amplifiers to be installed at greater distances along the network, reducing required components. Automatic Gain mode allows the amplifiers to intelligently alter gain levels independently as the system grows and changes. This mode reduces system maintenance considerably reducing your maintenance costs.

LOCAL DIAGNOSTICS

Local diagnostics are standard on all Becker Varis Amplifiers, this facilitates fault-finding and system troubleshooting by quickly being able to identify the component saving time and money.

• Local Diagnostics via 3 on board LED indicators

• Power On, RF Level OK Green LED

• Power On, RF Level Low Red LED

• Power On, RF Level High Yellow LED

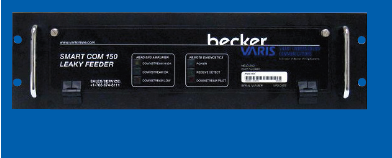

SMARTCOM® 150, BSC-AMP (NEW)

The Premium VHF Leaky Feeder at the right price for underground mines.

The smartcom® BSC-AMP provides customers a high value, robust, and low maintenance VHF communication platform to operate your mine effectively without the added expense of costly data radios for onboard telemetry functions. All this while maintaining the Ethernet and remote diagnostics functions that many customers have come to depend on.

BSC-AMP UPGRADE PATH

The new line amplifier has been designed so if customers’ needs change the unit can be upgraded to include onboard analogue and digital telemetry or built-in tag readers which is achieved by purchasing and installing an upgrade kit. The installation can be completed on-site and does not require the unit to be returned.

The upgrade kit allows for continued fast and reliable system expansion when the need arises.

The data is represented on the Remote Diagnostics Server User Interface installed on the surface or thru Becker Varis’ custom SCADA package.

smartcom® 150, RNG-AMP (ORIGINAL)

The smartcom® RNG-AMP provides the same robust and low maintenance VHF communication platform with remote diagnostics and is Ethernet capable standard.

The high-speed TCP/IP data transfer through the Leaky Feeder enables wired and wireless Ethernet applications such as control of fixed plant, where high-speed data is required; promptly install the smartcom® Cable Modem and 802.11b/g Access Point to create a small hotspot.

The 30MHz bandwidth provides a 54 Mbps downstream, 40.96 Mbps upstream Ethernet connection. Standard Ethernet equipment can be easily connected cost-effectively and is simple to install and maintain.

NO RETURN PILOT

Smartcom® does not require a return pilot signal to operate which is a valuable advantage for its users. In automatic mode the amplifier makes use of a forward pilot system that is superior to systems that utilize return pilot.

In Automatic mode the product monitors the RF strength of the forward pilot from the base station at each amplifier and adjusts automatically to ensure the communications network is running at its optimum even as the system is reconfigured.

Return pilots are the weakest link in any leaky feeder system as they are installed to control the gain of all amplifiers in the network if a pilot fails or cable is damaged. System components will adjust to maximum gain and create significant system noise-making voice communication difficult and frustrating.

Generally, return pilot systems require dedicated communication technicians or maintenance contracts with the OEMs to regularly maintain and monitor the communications system costing mines thousands of dollars in maintenance and reduces the overall safety and production benefits of the communication system.

AUTOMATION

The smartcom® product supports telemetry and can be effectively used for controlling underground equipment such as ventilation fans, pumps, stench gas firers and can provide desired information back to mine control systems effectively.

DIGITAL OR ANALOGUE RADIO SYSTEM

The smartcom® products supports both analogue and digital radio repeaters so customers have a choice of radio infrastructure they wish to install; again providing the customer flexibility and choice.

CUSTOMER SATISFACTION

The smartcom® product operates in hundreds of mines around the globe and customer satisfaction is unparalleled. Customer satisfaction is attributed to the ease of installation and maintenance and low operating cost which are key objectives when designing

our products.

PRODUCT DESIGN

Mines are inherently remote to major cities and towns making access to communication specialists and services difficult and costly for mining customers if systems are unreliable or require continuous maintenance. Reliable, Robust and Low Maintenance has been achieved with smartcom®.

SYSTEM COMPATIBILITY

The smartcom® amplifiers are compatible with other leaky feeder systems and can be easily installed in existing networks, when doing this the choice would be the new RNG-AMP units as Ethernet and Remote Diagnostics are only achieved when a complete network of Becker amplifiers are utilized.

Reviews

There are no reviews yet.