In addition to the motor control

parameters the system can

be expanded to include pump

monitoring parameters such as

bearing temperatures, flow, pressure

and vibration.

This information could be used to

provide the efficiency of the pump

thereby giving early warning as per

the health of the pump as well as the

ability to decide when the pump should

be maintained or rebuilt. Energy usage

per pump/efficiency per pump can

also be derived from this information.

SMART PHONES AND TABLETS

The system can be connected to

smart phones and tablets via wireless

ethernet and provide web browser

based information to the user

instantly.

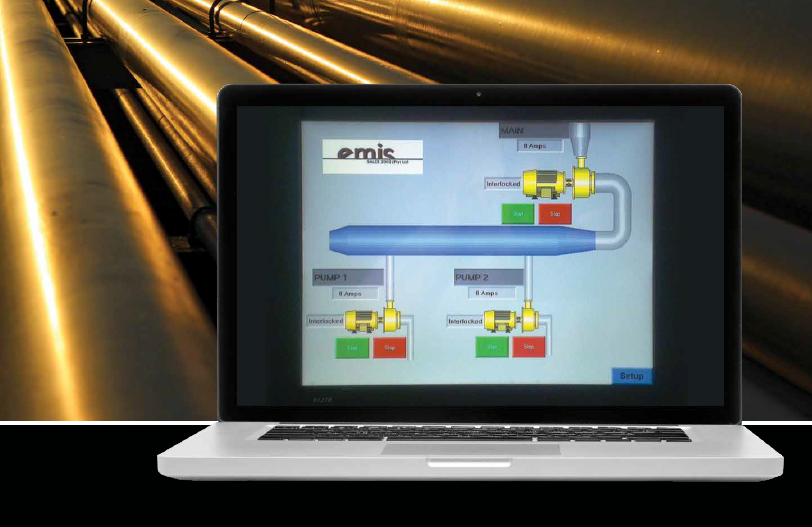

REMOTE ACCESS

The system can be connected to a

remote PC to control, fault finding or to

purely monitor the system status and

performance. This can be achieved on

RS485, ethernet or GPRS.

SCADA

The system is designed with the ability

to seamlessly integrate with any plant

SCADA using OPC Server or Modbus

RS485 or Modbus TCPIP. This will allow

all information to be shared upstream

with your supervisory system or SQL

database.

SMS AND EMAILS

The system has the ability to produce

SMS messages (normally Via GSM

cell networks) and even send emails

to notify yourself or your maintenance

staff to any abnormality or alarm

produced in the plant directly to their

mobile device (cell phone or smart

phone).

Reviews

There are no reviews yet.